Section 10 - Coupling Devices

- Hitch Assembly, Structure and Attaching Components

- Secondary Attachment (Safety Chain or Cable)

- Pintle Hook, Pin Hitch, or Coupler Hitch

- Ball Type Hitch

- Roll-Coupling Hitch

- Automated Coupling Device

- Fifth Wheel Coupler

- Oscillating Fifth Wheel Coupler

- Ball-Bearing Type Turntable on Trailer

- Permanently Mounted Equipment

All inspection procedures are visual unless additional inspection procedures are indicated or where applied force is necessary to verify tightness and/or component security. The definitions can be found in the “Definitions and Acronyms” section.

1. Hitch Assembly, Structure and Attaching Components

Note: This applies to all types of hitching systems and coupling devices. Some rust and corrosion on the outer surface of exposed metal parts is normal. When an excessive amount of rust or corrosion is present and has visibly reduced the thickness of the material, structural deterioration is possible.

Additional Inspection Procedure(s): Inspect using suitable tools.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) hitch assembly, receiver, drawbar or draw beam, slider, supporting structure and attachment to vehicle chassis | a) part is bent, broken or cracked weld is broken or cracked welded or repaired in a way that does not meet fastener is ineffective, or any part of hitch assembly is worn beyond specifications, abnormally deteriorated or perforated by corrosion hinged drawbar bushing is worn beyond specifications air leak, or from hydraulic components on any slider system any slider system has a or ineffective stop | 1, 2, 3, 4, 5, 6 |

i. any crack, break or damage in the stress or loading area of the coupling device or structure

ii. any component is or worn to the degree that it is no longer effective

iii. welded or repaired in a way that does not meet and an imminent failure appears likely

iv. air leak, or from hydraulic components on any slider system

v. any slider system has a or ineffective stop

2. Secondary Attachment (Safety Chain or Cable)

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

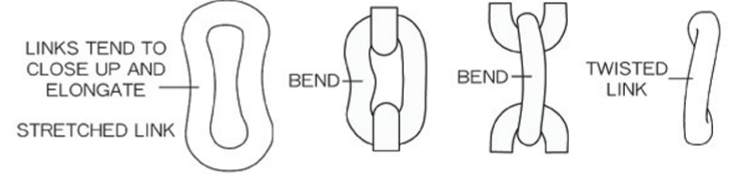

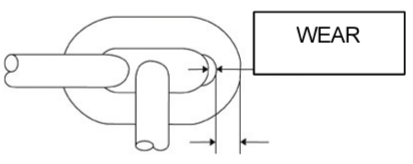

a) condition | a) bent, broken, cracked, , , or worn beyond specifications improper length any part is ineffective, , , or safety chain:

cable:

| 1, 2, 3, 4, 5, 6 |

b) cable clamps | b) insufficient quantity, incorrectly installed, | 1, 2, 3, 4, 5, 6 |

c) hooks | c) cracked, , part broken | 1, 2, 3, 4, 5, 6 |

d) safety catches | d) operate ineffectively, | 1, 2, 3, 4, 5, 6 |

i. any component is broken, cracked, or

ii. bent, , improperly repaired, , or worn to the degree that it is no longer effective

iii. improper type or inadequate capacity

3. Pintle Hook, Pin Hitch, or Coupler Hitch

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition and operation Additional Inspection Procedure(s): Test the operation of the pintle hook and latch. | a) cracked, or fails to close or latch normally latch mechanism worn to beyond the | 1, 2, 3, 4, 5, 6 |

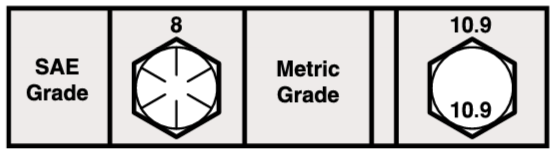

b) mounting | b) fastener or any structural part is cracked, ineffective, or a fastener is less than grade 8 or ISO class 10.9 | 1, 2, 3, 4, 5, 6 |

c) cast or forged part | c) cracked, or has been repaired by welding material is worn to beyond the | 1, 2, 3, 4, 5, 6 |

d) air chamber cushion (no-slack or snubber) Additional Inspection Procedure(s): Apply air pressure to air chamber and inspect according to hitch service instructions and specifications. | d) or leaking air chamber leak at air line or fitting pressure protection valve is not installed in air supply to prevent depletion of air from the brake system modified in a way that does not meet the | 1, 2, 3, 4, 5, 6 |

e) lunette (or drawbar eye) on trailer | e) cracked, or is worn to beyond the | 3 |

i. wear on hitch or lunette (eye) exceeds 10 mm

ii. any component is broken, cracked, or

iii. bent, , improperly repaired, , or worn to the degree that it is no longer effective

iv. improper type or inadequate capacity

v. or ineffective fastener

vi. latch

4. Ball Type Hitch

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) ball, neck and stem | a) bent, cracked or ball is worn more than 3.0 mm from original dimension welded, or repaired in a way that does not meet 3.0 mm = 0.12 in. | 1, 2, 3, 4, 5, 6 |

b) ball deck area | b) part is bent, broken or cracked weld is broken or cracked welded or repaired in a way that does not meet | 1, 2, 3, 4, 5, 6 |

c) ball coupler | c) bent, cracked or abnormally deteriorated or perforated by corrosion | 1, 2, 3, 4, 5, 6 |

d) latch Additional Inspection Procedure(s): Test the operation of the latch. | d) bent, broken or cracked or fails to adjust properly weld is broken or cracked | 1, 2, 3, 4, 5, 6 |

i. wear on ball exceeds 3.0 mm

ii. any component is broken, cracked, or

iii. bent, , improperly repaired, , or worn to the degree that it is no longer effective

iv. improper type or inadequate capacity

v. or ineffective fastener

vi. latch

5. Roll-Coupling Hitch

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition | a) part is bent, broken or cracked weld is broken or cracked welded or repaired in a way that does not meet fastener is ineffective, or any fastener is smaller than specified by the or less than grade 8 or ISO class 10.9 any load bearing structural part of the hitch assembly is deteriorated or perforated by corrosion | 2, 3, 4, 5 |

b) operation Additional Inspection Procedure(s): Test the operation of the coupling and controls according to the service instructions. | b) | 2, 3, 4, 5 |

i.

ii. any component is broken, cracked, or

iii. bent, , improperly repaired, or

iv. improper type or inadequate capacity

v. or ineffective fastener

6. Automated Coupling Device

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition Additional Inspection Procedure(s): Test the operation of the coupler according to the | a) welded or repaired in a way that does not meet | 2, 3, 4, 5 |

i. fails to operate in the intended manner

ii. any component is broken, cracked, or

iii. bent, , improperly repaired, , or worn to the degree that it is no longer effective

iv. improper type or inadequate capacity

v. or ineffective fastener

7. Fifth Wheel Coupler

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) upper coupler (pick up plate) on trailer Additional Inspection Procedure(s): Check the condition and flatness of the upper coupler plate using a tool specifically intended for that purpose or an equivalent measuring device. | a) cracked, , warped or worn so that the area in contact with the lower fifth wheel is less than 75% of the surface of the lower coupler bent upward or downward more than specified by lubricant is contaminated with an abrasive material upper coupler’s attachment or a structural member is corroded, or in a condition that the plate or king pin is weakened mounting bolt or rivet is broken, corroded, or (also refer to Section 8 - Item 6 - Frame, Rails & Mounts) bulge is present in attaching and mating surface due to corrosion rivet is dimpled due to corrosion rivet area bulged due to corrosion | 1, 2, 3, 4 |

b) kingpin on trailer (or on towing vehicle) Additional Inspection Procedure(s): Check the wear and condition of the kingpin using a gauge specifically intended for that purpose or an equivalent measuring device. | b) bent, broken, cracked, deformed or worn more than 3.0 mm repaired by welding length is incorrect to properly fit into fifth wheel jaws Note: A fifth wheel intended for use with a material installed on the lower coupler, instead of applying grease, requires a longer king pin length. A king pin intended for use with a material installed on the lower coupler, instead of applying grease, does not properly couple with a standard fifth wheel. | 1, 2, 3, 4 |

c) lower coupler (fifth wheel) top plate | c) any part is broken, cracked, , distorted, or welded, or repaired in a way that does not meet standard surface is worn beyond specified limit wear in pivot pin is beyond specified limit lubricant is abnormally contaminated, (e.g. sand, gravel) not properly lubricated (unless equipped with supplied no-lube top plate coupling surface) | 1, 2, 3, 4 |

d) latching mechanism Additional Inspection Procedure(s): Test the operation of the latch, and wear in the fifth wheel assembly, using a test device specifically designed for that purpose or a suitable equivalent. | d) broken, cracked or stiffness or seizing of the latch mechanism is felt free-play, slack or wear is beyond specified limit improperly adjusted modified or improperly repaired release handle is bent, modified or has anything attached to it | 1, 2, 3, 4 |

e) lower coupler pivot (‘fifth wheel saddle’) Additional Inspection Procedure(s): Check for wear in the fifth wheel pivot area according to service instructions. | e) wear exceeds specification | 1, 2, 3, 4 |

f) slider assembly and locking mechanism | f) any part is bent, broken, cracked, or fore/aft movement of fifth wheel in slider exceeds specification fails to lock securely slider stop is or | 1, 2, 3, 4 |

g) air-operated control or feature | g) Note: Do not reject if air cylinder rendered by airline removal. | 1, 2, 3, 4 |

h) upper and lower coupler attachment to frame | h) any part is broken, cracked, , distorted, , or welded or repaired in a way that does not meet standard any fastener is cracked, ineffective, or fasteners used to attach coupler assembly to frame do not meet the minimum requirements shown in the table below | 1, 2, 3, 4 |

Minimum Number of Bolts per Side Based on Type & Size of Bolt | ||||||

|---|---|---|---|---|---|---|

Minimum trailer | ASTM A325 Type 1,2&3 (metric 5.8) | J429 | J429 | |||

1/2’’ | 5/8’’ | 1/2’’ | 5/8’’ | 1/2’’ | 5/8’’ | |

67,999 lb (30,845 kg) or less | 6 | 4 | 6 | 4 | 5 | 4 |

68,000 – 84,999 lb | 8 | 5 | 8 | 5 | 7 | 5 |

85,000 – 105,000 lb | 10 | 6 | 10 | 6 | 8 | 5 |

Bolt size refers to the outside diameters of the thread.

| ||||||

i. adjustable fifth wheel has 25% or more of the locking pins

ii. any observable movement between the fifth wheel, or upper coupler, mounting components and/or the frame

iii. more than 9 mm fore/aft movement of the fifth wheel in its sliding track

iv. any sliding fifth wheel locking mechanism does not remain in the locked position

v. any crack, break or damage in the stress or loading area of the coupling device

vi. slider stop is or

vii. more than 25 percent of latching fasteners on either side of slider are ineffective

viii. pivot bracket pin or not secured

ix. any parent metal cracked

x. any repair weld cracking, well defined (especially open) cracks in stress or load-bearing areas, cracks through 20% or more original welds or parent metal

xi. operating handle not in closed or locked position

xii. more than 20 percent of mounting fasteners on either side or ineffective

xiii. locking mechanism parts broken, , or deformed to the extent that the kingpin is not securely held

xiv. kingpin is bent, broken, cracked, deformed or

xv. any trailer with a bolted upper coupler, which has fewer effective bolts than shown in table above

8. Oscillating Fifth Wheel Coupler

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) oscillating components and structure Additional Inspection Procedure(s): Check for wear and defects according to service instructions. | a) cracked, , defective or wear exceeds specification | 1, 2, 3 |

Refer to hazardous conditions in item 7 above.

9. Ball-Bearing Type Turntable on Trailer

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition Additional Inspection Procedure(s): | a) bolt or cracks in weld or parent metal wear exceeds specification binding, lack of lubrication or evidence of imminent failure | 3 |

i. top flange has less than 6 effective bolts

ii. bottom flange has less than 6 effective bolts

iii. twenty percent or more of original welds (or repaired original welds), or parent metal cracked

iv. upper flange half touching lower flange half

v. cracked flanges

10. Permanently Mounted Equipment

Note: Permanently mounted equipment has the same meaning as defined in the Commercial Transport Regulations, Division 1.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) security | a) or | 2, 3, 4 |