Section 8 - Frame and Body

- Hood or Engine Enclosure

- Tilt Cab

- Air-Suspended Cab

- Vehicle Body

- Cargo Body

- Frame, Rails & Mounts

- Doors

- Cargo Tank or Vessel

- Body, Device or Equipment Attached or Mounted to the Vehicle

- Refrigeration/Heater Unit System (Reefer or Auxiliary Power Unit [APU])

- Bumpers

- Windshield

- Side Windows

- Rear Window

- Interior Sun Visor

- Exterior Windshield Sun Visor

- Rear-view Mirror

- Seat

- Seat Belt/Occupant Restraint

- Fender/Mudflap

- Landing Gear on Trailer

- Sliding Axle Assembly (Sliding Bogie) on Trailer

- Aerodynamic Device and Attachment

- Rear Impact Guard (RIG) on Trailer

- Floor Pan/Baggage Floor/Step Well on a Bus

- Interior Body and Fixtures on a Bus

- Service and Exit Door on a Bus

- Emergency Exit (Door, Window and Roof Hatch) on a Bus

- Passenger Compartment Window on a Bus (Except Emergency Exit Window)

- School Bus Exterior Mirror (Except Standard Left and Right Side Mirror)

- Passenger Seat on a Bus

- School Bus Body Exterior

- Auxiliary Compartment on a Bus

- Motorcycle Sidecar

- Accessories

All inspection procedures are visual unless additional inspection procedures are indicated or where applied force is necessary to verify tightness and/or component security. The definitions can be found in the “Definitions and Acronyms” section.

1. Hood or Engine Enclosure

Additional Inspection Procedure(s): Test the operation of the hood or engine enclosure doors, attachment, latches and safety devices.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition | a) , , or deteriorated in a manner that it is likely to become detached or | 1, 2, 4, 5 |

b) latch (primary or secondary) | b) broken, , mounting, or seized effectiveness is compromised due to deteriorated condition, (e.g.: rubber or similar type of latch) fails to open or close normally welded or repaired in a way that does not meet | 1, 2, 4, 5 |

c) safety cable, assist spring, support/dampener | c) broken, attached or | 1, 2, 4, 5 |

d) hinge and support spring | d) hinge or hinge part is broken, cracked, , seized or | 1, 2, 4, 5 |

e) safety retainer pins | e) , broken, , inferior substitute | 1, 2, 4, 5 |

f) hood reinforcement Additional Inspection Procedure(s): When rejection criteria is marked with [ | f) reinforced other than by a method approved by:

[ | 1, 2, 4, 5 |

i. both primary and secondary latch are

2. Tilt Cab

Additional Inspection Procedure(s): Test the operation of the tilt cab operation, its attachment, latches and safety devices.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) latch (primary or secondary) | a) broken, mounting, or seized fails to open or close normally welded or repaired in a way that does not meet | 2 |

b) hinge | b) hinge or hinge part is broken, cracked, , seized or parts do not align correctly | 2 |

i. latch fails to secure the cab (latch is incapable of holding cab from moving forward)

3. Air-Suspended Cab

Additional Inspection Procedure(s): Check the cab with air system at normal operating pressure.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) air bag | a) leaking, cracked to reinforcing layer, or patched not properly inflating or cab tilts to one side | 2 |

b) air line, connection and fitting | b) fitting, line or repair method does not meet the or if there is no tubing or hose is defective as defined in Appendix B fitting or connection is broken, cracked, flattened or leaking in a way (such as: melting, flattening, deformation or kinking) that can restrict air flow | 2 |

c) mount, rod and attachment | c) bent, broken, or welded or repaired in a way that does not meet | 2 |

d) pressure protection valve | d) or improper type | 2 |

e) height control valve | e) (as indicated by cab height being above or below its normal position) equipped with a single valve which is not in location, or not near centre of cab | 2 |

f) shock absorber | f) broken, , disconnected, or | 2 |

i. any component is so or that it is an imminent hazard or it could become detached from vehicle

4. Vehicle Body

4.1. Body-On-Frame

Additional Inspection Procedure(s):

When rejection criteria is marked with [![]() ] symbol, and the vehicle meets the criteria, it must be referred for a structural integrity assessment.

] symbol, and the vehicle meets the criteria, it must be referred for a structural integrity assessment.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition | a) any section or panel is in a condition that could be hazardous to driver, passenger, pedestrian or cyclist due to being: , protruding, torn or having an exposed sharp edge [ [ body component integrity is reduced due to a body component, broken weld, fastener or failed adhesive hole is present in panel or floor body panel or floor is welded or repaired in a way that does not meet | 1, 2, 3, 4, 5 |

b) body mount/support | b) allows abnormal amount of movement broken, cracked, or parts improper mount used support cracked, broken or bulging welded or repaired in a way that does not meet | 1, 2, 3, 4, 5 |

c) body moulding or trim | c) is in a condition that could be hazardous to driver, passenger, pedestrian, or cyclist due to being: , protruding, torn or having an exposed sharp edge | 1, 2, 3, 4, 5, 6 |

d) fender, quarter panel and mudflap Note: For exemptions, see Item 20 in this section. | d) , so that road spray is not controlled corroded or in a manner that type lamps cannot be properly secured not the full width of the tire(s) fitted so that it could cause interference with steering mechanism or cause rubbing of tires when suspension bottomed and steering moved stop to stop (includes rear wheels) | 1, 2, 3, 4, 5 |

e) body lift Additional Inspection Procedure(s): Height measurements must be recorded for headlights, front bumper, tire size and overall vehicle height. | e) vehicle modification or components not safe for use on highway | 1, 2, 4 |

4.2. Unibody

Note: Repairs to perforated metal floor pans require patches and repairs to be or welded with the same gauge metal as the pan.

Additional Inspection Procedure(s):

When rejection criteria is marked with [![]() ] symbol, and the vehicle meets the criteria, it must be referred for a structural integrity assessment.

] symbol, and the vehicle meets the criteria, it must be referred for a structural integrity assessment.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) floor pan | a) [ [ | 1, 2, 4, 5 |

b) strut towers and spring shackle supports | b) [ [ | 1, 2, 4, 5 |

c) body panels | c) [ | 1, 2, 4, 5 |

d) high strength, front and rear structural side members | d) [ [ | 1, 2, 4, 5 |

e) welding | e) [ [ | 1, 2, 4, 5 |

f) unibody sheet metal | f) [ | 1, 2, 4, 5 |

g) load carrying panel, bulkhead, structural element and mounts Note: Some rust and corrosion on the outer surface of exposed metal parts is normal. When a high amount of rust or corrosion is present and visibly reduces the thickness of the material, structural deterioration is possible. | g) bent, broken, cracked, or welded or repaired in a way that does not meet any rivet is or any condition of the unibody allows a part of the body or power train, out of its normal position, or to contact a moving part | 1, 2, 3, 4, 5 |

i. any component is so or that it is an imminent hazard or it could become detached from vehicle

ii. any section has exposed sharp edge, is torn or protrudes out in a manner that is hazardous to driver, passenger, pedestrian or cyclist

iii. any body part or attachment is broken, cracked perforated, or sagging, in a manner that permits the body to contact any moving part

iv. imminent failure appears likely due to a body component that is or deteriorated, or has been repaired using material or method, that does not meet the or if there is no

v. structural body component has a crack, cut or notch longer than 38 mm

vi. any condition of a unitized body component allows a part of the body or power train to be more than 38 mm out of its normal position, or to contact a moving part

5. Cargo Body

Note: Minor surface rust and corrosion is normal.

Additional Inspection Procedure(s): Where any sheet metal, structural item or fastener is suspected of being or perforated, determine the integrity of the suspect item or area by lightly tapping it with a hammer.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) sheet metal | a) any section has exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to driver, passenger, pedestrian or cyclist panel is , or corroded through rivet is , welded or repaired in a way that does not meet | 1, 2, 3 |

b) floor & deck | b) has any condition that allows a person or cargo to fall through has a hole larger than 200 mm across the longest dimension welded or repaired in a way that does not meet | 1, 2, 3 |

c) frame & sub-frame | c) bulge caused by corrosion resulting in distortion of 10 mm or more (unless the condition or the repair is approved by the , or an engineer) stress crack at side rail or rub-rail rivet is , , dimpled by corrosion bent, broken, cracked or welded or repaired in a way that does not meet | 1, 2, 3 |

d) cross-member | d) bent, broken, collapsed, cracked or perforated or weakened by corrosion | 1, 2, 3 |

e) inner or outer side rail and body-long sills | e) bulge caused by corrosion resulting in distortion of 10 mm or more (unless the condition or the repair is approved by the , or an engineer) rivet is , bent, broken, cracked or welded or repaired in a way that does not meet | 1, 2, 3 |

f) stake pocket/tiedown, cargo securing point or cargo securing device (including portable anchors) | f) broken, cracked or elongated or distorted | 1, 2, 3 |

g) tailgate, hopper, or end-dump door | g) broken, or cracked hinge is broken, cracked or , or pin lock is , or will not close and latch properly any gap exists that would allow leakage, loss or spillage of cargo welded or repaired in a way that does not meet standard | 1, 2, 3 |

h) body to frame attachment Note: Includes body to frame attachment device such as U-bolt, pivot hinge, cheek plate mount, flex-mount hardware, body clamp and J-Bar. | h) bent, broken, cracked, or spring is broken spacer or insulator is , crushed, dislodged or | 1, 2, 3 |

i) body rail and structural member | i) upper or lower cargo body rail is bent, buckled, has a crack longer than 25 mm, or has a fastener or floor cross member is bent, or sagging roof support is bent, or sagging | 1, 2, 3 |

j) body panel | j) any section has exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to driver, passenger, pedestrian or cyclist panel or panel fastener is , , , or corroded through rivet is repaired in a way that does not meet any gap exists that would allow leakage, loss or spillage of cargo | 1, 2, 3 |

k) bunk and stake equipment | k) bunks are broken, cracked, mounted or bolts are ; bunk lash exceeds 5 mm or bunk posts, stakes and extensions are broken, cracked, , or bolts are ; angle exceeds 90 degrees cup and saucer cracked, broken, worn beyond stake cables are less than 21 mm (7/8 in.) in diameter, worn, frayed, pinched, anchor , stake trip lever retainer , trip stake return spring or broken bolster is or cracked, bolts are or bunk air lock has an air leak or not functioning as per | 1, 2, 3 |

i. any component is so or that it is an imminent hazard or it could become detached from vehicle

ii. any section has exposed sharp edge, is torn or protrudes out in a manner that is hazardous to driver, passenger, pedestrian or cyclist

iii. any body part or attachment is broken, cracked perforated, or sagging, in a manner that permits the body to contact any moving part, or imminent collapse appears likely

iv. any gap exists allowing leakage, loss or spillage of cargo

v. a cargo body upper or lower rail is buckled, bowed, cracked through, sagging or has two or more adjacent or fasteners

vi. two or more adjacent floor cross members are bent, or sagging

vii. two or more adjacent roof supports are bent, or sagging

5.1. Body Type - Low Boy

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) tie downs | a) , broken, cracked, worn beyond load security specifications | 3 |

b) loading ramp (if equipped) | b) hinges broken, mounted | 3 |

c) equipment rails or pads (floor not required) | c) , | 3 |

d) side rails (if equipped) | d) , cracked, broken, corroded through, , improper or inadequate repair | 3 |

e) cross-member | e) bent, broken, collapsed, cracked or perforated or weakened by corrosion | 3 |

f) detachable neck | f) worn, cracked, , or it could become detached locking components worn beyond | 3 |

i. any component is so or that it is an imminent hazard or it could become detached from vehicle

5.2. Body Type - Timber/Log/Pole

Additional Inspection Procedure(s): Where bunk/scale pad bolts are present, all bolts must be torqued to . Use of a torque multiplier may be required.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) bunks/bunk lash | a) broken, cracked, mounted , bolts, bunk lash exceeds 5 mm (3/16 in.) or repaired in a manner that does not meet the | 2, 3 |

b) bunk posts, stakes and extensions | b) broken, cracked, , bolts, angle exceeds 90 degrees hinge bushings/pins repaired in a manner that does not meet the | 2, 3 |

c) cup and saucer | c) cracked, broken, , does not meet | 2, 3 |

d) stake cables | d) less than 21 mm (7/8 in.), worn, frayed, pinched, corroded through, anchor , stake trip lever retainer , trip stake return spring or broken | 2, 3 |

e) bolster | e) , cracked, bolts , | 2, 3 |

f) reach (entire length of reach must be inspected) | f) cracked, worn more than 20%, bent, repairs do not meet | 2, 3 |

g) compensator | g) live (stops ), cracked, welded, worn more than 20% bushings fasteners or | 2, 3 |

h) adjustable reach (trailers manufactured after January 1, 1993) Additional Inspection Procedure(s): All sections of reach must be fully extended for inspection. | h) repaired by welding bolts or positive means other than a friction clamp to prevent movement are | 2, 3 |

i. any component is so or that it is an imminent hazard or it could become detached from vehicle

5.3. Body Type - Cattle Liner

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) sides | a) cracked, corroded through, severely corroded as to weaken the member (check by tapping with hammer) rivets at drop center front and back are , , working | 2, 3 |

b) floor Note: Particular attention should be given at drop center area. | b) cracked, corroded through, severely corroded as to weaken the member (check by tapping with hammer) rivets at drop center front and back are , , working | 2, 3 |

c) side supports Additional Inspection Procedure(s): Visually inspect the supports from inside and outside of the body. | c) , broken, cracked, corroded through, corroded so as to weaken the support | 2, 3 |

d) side rails | d) bulges indicating corrosion evident, stress cracks at rails rivets dimpled, rivets (check by tapping rivets with hammer) | 2, 3 |

i. any component is so or that it is an imminent hazard or it could become detached from vehicle

6. Frame, Rails & Mounts

Additional Inspection Procedure(s):

When rejection criteria is marked with [![]() ] symbol, and the vehicle meets the criteria, it must be referred for a structural integrity assessment.

] symbol, and the vehicle meets the criteria, it must be referred for a structural integrity assessment.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition Additional Inspection Procedure(s): With the vehicle raised (if applicable) tap with ball peen hammer. Note: Some rust and corrosion on the outer surface of exposed metal parts is normal. When a high amount of rust or corrosion is present and visibly reduces the thickness of the material, structural deterioration is possible. | a) welded, modified or repaired in a way that does not meet welded and heated areas corrosion resistant coating [ [ rusted, worn or corroded to a depth sufficient to become weakened bulge caused by corrosion resulting in distortion of 10 mm or more (unless the condition or the repair is approved by the , or an engineer) any condition of the frame assembly allows a frame component, or a part of the body or power train, out of its normal position, or to contact a moving part, or affects the ability to maintain the wheel alignment within the specified range body mounts split, broken, , bolts frame flexes, is cracked or welded or has fatigue points to the extent that structural damage is indicated unable to certify frame is suitable for highway use | 1, 2, 3, 4, 5, 6 |

b) frame fastener | b) ineffective, or | 1, 2, 3, 4, 5, 6 |

c) cross-member | c) bent, broken, cracked, or cut, notched, rusted or corroded to a depth sufficient to cause weakness repaired using material or method, that does not meet the or if there is no any condition of a cross member allows a frame component, or a part of the body or power train, out of its normal position, or to contact a moving part | 1, 2, 3, 4, 5 |

d) sub-frame assembly Note: This only applies to a structural frame assembly that is not part of the main frame or unibody assembly, and carries a load or provides strength to the vehicle structure, i.e.: engine cradle, or suspension sub-frame. | d) bent, broken, cracked, or cut, notched, rusted or corroded to a depth sufficient to cause weakness repaired using material or method that does not meet the or if there is no any condition of the sub-frame assembly allows a frame component, or a part of the body or power train, out of its normal position, or to contact a moving part, or affects the ability to maintain the wheel alignment within the specified range | 1, 2, 3, 4, 5, 6 |

e) footrest | e) no footrests for operator, or for the passenger if equipped with room for a passenger on seat | 6 |

i. any frame side-rail or cross-member is cracked as follows:

longer than 38 mm

longer than 25 mm in the bottom flange

from the web extending around the radius and into the bottom flange

ii. any condition of the frame allows a frame component, or a part of the body or power train, to be more than 38 mm out of its normal position, or to contact a moving part

iii. imminent failure appears likely due to a frame member that is or deteriorated, or has been repaired using material or method, that does not meet the or if there is no

iv. frame broken or twisted out of alignment

7. Doors

7.1. Cab and Passenger-Vehicle Doors

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition and operation Additional Inspection Procedure(s): Note: This includes a partition door between the occupant and cargo area. | a) , binds or fails to lock securely mounting to hinge, hinge or severely corroded in hinge area hinges are cracked, , or panel is corroded through welded or repaired in a way that does not meet door fails to operate or latch on both primary and secondary latches gap exists that may allow exhaust gases to enter cab, passenger compartment, and/or sleeper seal is out of position, or , and is able to allow exhaust gases to enter cab, passenger compartment, and/ or sleeper any gap exists that would allow leakage, loss or spillage of cargo | 1, 2 |

b) door openers and handles | b) broken, or on modified collector vehicles only - inner door release mechanism not readily available or identified Note: If outer door handles are removed (shaved), inner door release mechanism must be readily available and identified. | 1, 2 |

c) location | no exit on one side exits are | 1, 2 |

d) intrusion beam | d) , , broken, bent, kinked, repaired other than by an approved standard and process | 1, 2 |

e) door panel | e) repaired in a manner that compromises structural integrity, repaired other than by an approved standard and process | 1, 2 |

f) trunk door | f) will not open, close and latch seal cracked, broken or interior trunk release or Note: Every passenger car and manufactured after September 1, 2010 must be equipped with an interior trunk release (CMVSS 401). | 1, 2 |

7.2. Cargo Doors

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition and operation Additional Inspection Procedure(s): | a) , binds or fails to lock securely mounting to hinge, hinge or severely corroded in hinge area panel is corroded through welded or repaired in a way that does not meet door fails to operate or latch on both primary and secondary latches seal is out of position, or , and is able to allow exhaust gases to enter cab, passenger compartment, and/ or sleeper any gap exists that would allow leakage, loss or spillage of cargo | 1, 2, 3 |

b) door openers and handles | b) broken, or | 1, 2, 3 |

i. cab door fails to latch on both primary and secondary latches

ii. cargo door fails to latch

iii. gap exists and exhaust gases are entering cab, passenger compartment or sleeper

iv. any gap exists allowing leakage, loss or spillage of cargo

8. Cargo Tank or Vessel

Note: Dangerous goods, edible product, dry bulk cargo tanks are frequently subject to additional inspection requirements (see Code B620). Inspections conducted in accordance with this standard address only a limited portion of the compliance requirements.

This inspection does not include any procedure that requires operation of any valve, hatch or product handling item. Authorized Inspectors must take precautions to avoid exposure to any cargo or residual material.

If cargo tank test/inspection is expired, and the vehicle is no longer used to transport dangerous goods, the B620 standard may not apply (i.e., internal valve no longer required).

Note on the inspection report that the cargo tank inspection has expired.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition | a) welded or repaired in a way that does not meet on mounts of any liquid transported by the tank or vessel crack or broken weld in tank, frame or support movement, bulge or weakness caused by corrosion between tank and frame | 2, 3 |

b) valve | b) cap or of any liquid transported by the tank or vessel | 2, 3 |

c) hose | c) or improperly secured | 2, 3 |

d) hatch | d) , or latch hinge, broken or | 2, 3 |

i. any component is so or that it could become detached from vehicle

ii. required internal valve is

iii. internal valve remains open when it is required to be closed

iv. access/fill/inspection opening cover is improperly secured or

v. required venting device, emergency device, or discharge valve, is

9. Body, Device or Equipment Attached or Mounted to the Vehicle

Note: This section applies primarily to external devices or equipment attached to a vehicle. Examples include a crane, cargo lifting and transporting machine, load covering equipment, cargo dispensing equipment, APU, refrigeration-heater (reefer) unit, generator, ready-mix unit, sander body, feed & grain body, snowplow, service/utility body, vacuum tank, flatbed, roll-on/roll-off, lugger, ISO container chassis, etc.

The criteria in this section only apply to a mounted body, device or equipment to the extent that the condition could affect the safe operation of the vehicle on the highway. The functionality of the mounted equipment does not need to be tested or inspected.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) security and condition Additional Inspection Procedure(s): | a) equipment or device is in such an unsafe condition that is a risk to other motorists, the driver, a passenger, pedestrian or cyclist equipment or device is or , or in danger of shifting in a way that could impede normal operation of the vehicle any section has an exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to the driver, a passenger, pedestrian or cyclist of any oil, hydraulic fluid or liquid product | 1, 2, 3, 4, 5 |

i. any article, component or device is so or that it could become detached from vehicle

ii. equipment or device is in such an unsafe condition that is a risk to other motorists, the driver, a passenger, pedestrian or cyclist

iii. any section has an exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to the driver, a passenger, pedestrian or cyclist

10. Refrigeration/Heater Unit System (Reefer or Auxiliary Power Unit [APU])

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) security and condition Additional Inspection Procedure(s): Inspect the exhaust system and fuel system, according to the appropriate type of fuel used, as described in Section 1 – Power Train. | a) equipment or device is in such an unsafe condition that is a risk to other motorists, the driver, a passenger, pedestrian or cyclist equipment or device is or , or in danger of shifting in a way that could impede normal operation of the vehicle any section has an exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to the driver, a passenger, pedestrian or cyclist of any oil, hydraulic fluid or liquid product | 1, 2, 3, 4, 5 |

i. any article, component or device is so or that it could become detached from vehicle

ii. equipment or device is in such an unsafe condition that is a risk to other motorists, the driver, a passenger, pedestrian or cyclist

iii. any section has an exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to the driver, a passenger, pedestrian or cyclist

11. Bumpers

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition | a) broken, or any section has exposed sharp edge, is torn or protrudes in a manner that could be hazardous to the driver, a passenger, pedestrian or cyclist | 1, 2, 4, 5 |

b) design | b) replacement part does not meet , or does not provide the same protection as the bumper originally installed by the solid portion does not extend from one frame rail to the other (except for a unitized body design) | 1, 2, 4, 5 |

c) shock absorber and/or impact absorber (as ) | c) collapsed, welded to rail, solid or not collapsible | 1, 2, 4 |

d) height | d) on vehicles with a of 4536kg or less: centre of bumpers not between 180 and 560 mm (7 and 22 in.) from the ground for modified collector vehicles only centre of bumpers not between 400 and 560 mm (16 and 22 in.) from the ground for all other passenger cars lowest part of truck bumpers higher than 750 mm (29.5 in.) from the ground as measured to bumper location (frame rails) for trucks Note: Rear bumper required on trucks if equipped. on vehicles with a of more than 4536kg: lowest part of front bumper is higher than 750 mm (29.5 in) from the ground Note: Applies only to the front bumper on a truck or truck-tractor. Applies to the front and rear bumper on a . | 1, 2, 4, 5 |

i. imminent failure appears likely

ii. any section has exposed sharp edge, is torn or protrudes in a manner that could be hazardous to the driver, a passenger, pedestrian or cyclist

12. Windshield

Neighbourhood Zero Emissions Vehicles (NZEV) required equipment.

Note: Driver’s vision is materially impaired if it meets the definition set out in section 29 of the Schedule to Division 7 of the MVAR.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) obstruction Note: Forward/rearward facing camera safety devices may be mounted up to 50 mm from the outer edge of the area swept by wipers. | a) decal or device unduly obstructs driver’s vision Note: Windshield wipers must meet the criteria set in Section 5 of this Vehicle Inspection Manual. | 1, 2, 4, 5, 6 |

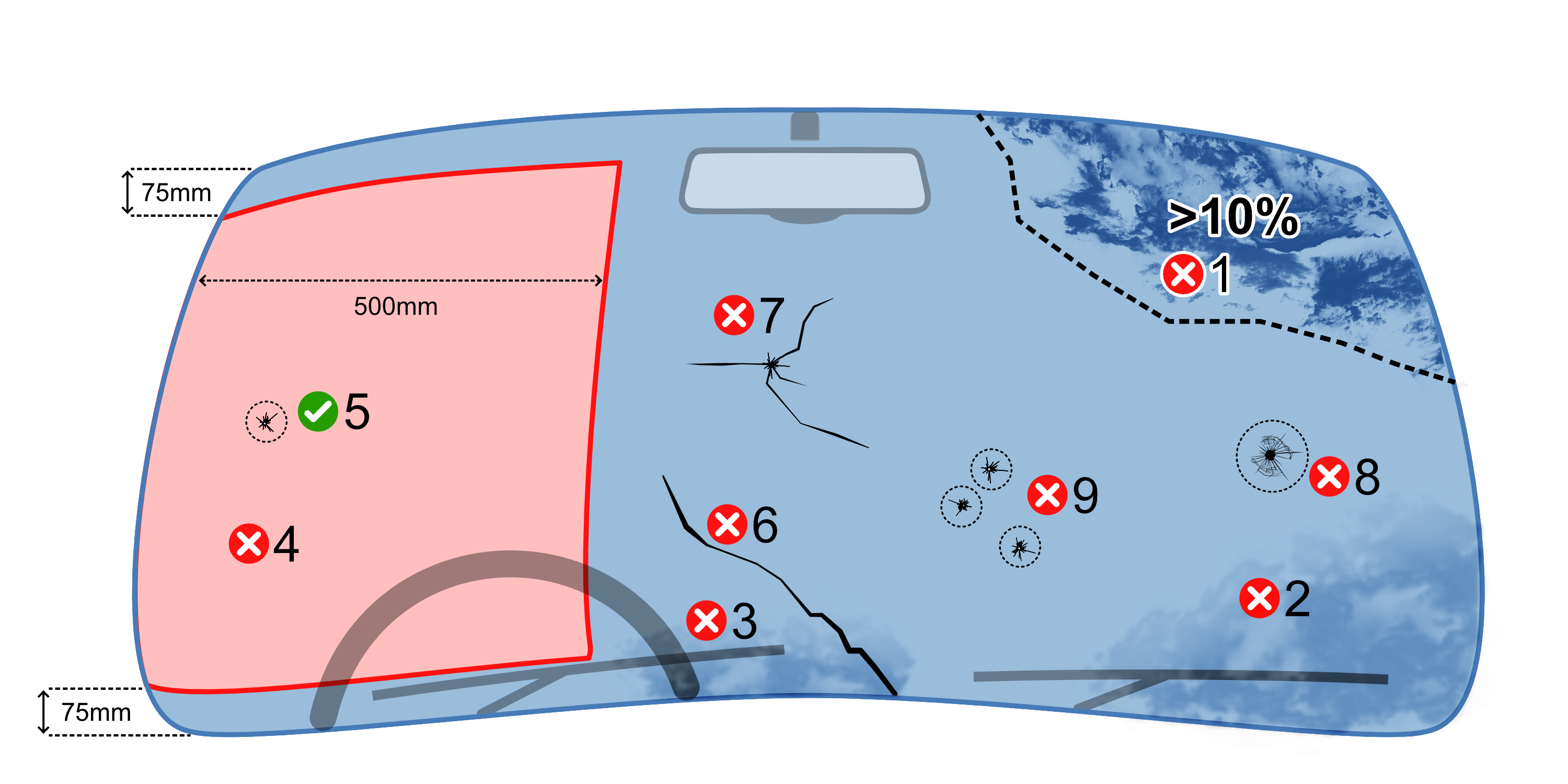

b) condition | b) any portion of windshield glass or the complete windshield glass area is clouded, or deteriorated in such a way that driver’s normal vision is materially impaired cracked, broken or clouded forward of a line parallel with the driver's shoulder vision is obscured or limited due to surface condition 1 more than 10% of total glass area is discoloured due to age or other deterioration 2 more than 75 mm clouding around the edge; 3 any clouding on the driver's side broken glass showing sharp edge only: 4 a defect in the area extending from the left side of the driver's side 500 mm toward the centre and extending over 75 mm down from the top or over 75 mm up from the bottom, 5 excepting small stone injuries of 6 mm or less only: a defect in the area extending from the right side of the driver's side 500 mm toward the centre and extending over 75 mm down from the top or over 75 mm up from the bottom, excepting small stone injuries of 6 mm or less | 1, 2, 4, 5, 6 |

c) crack | c) a crack extends through both layers of glass 6 a crack over 300 mm (12 in.) long in any part 7 more than 2 cracks over 150 mm long in any one piece of glass | 1, 2, 4, 5, 6 |

d) chip | d) 8 stone or shot injuries more than 40 mm in diameter 9 two or more stone or shot injuries over 20 mm in diameter in any one piece of glass | 1, 2, 4, 5, 6 |

e) tinting (MVAR 7.05(8)) | e) any after-market tint is applied unless the material is affixed to or placed on the windshield but not more than 75 mm below the top of the windshield tint or sunscreen other than that allowed by /Z26.1 standards any tint that is reflective type driver’s normal vision is materially impaired | 1, 2, 4, 5, 6 |

f) material type Note: Applies to all vehicles manufactured on and after January 1, 1971. | f) not marked as type AS-1, AS-10, AS-11C or AS-14 on all vehicles except on a not marked as type AS-1, AS-6, AS-10, AS-11A or AS-11C | 1, 2, 4, 5, 6 |

g) adhesive sealant | g) not automotive urethane type or is any type other than specified by the | 1, 2, 4, 5, 6 |

i. windshield is

ii. windshield is or deteriorated in such a way that driver’s normal vision is materially impaired

13. Side Windows

Note: Driver’s vision is materially impaired if it meets the definition set out in section 29 of the Schedule to Division 7 of the MVAR.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) operation Additional Inspection Procedure(s): | a) fails to open or close normally | 1, 2, 4, 5 |

b) condition Note: Applies to any window forward of the driver’s seat back. | b) clouded, or deteriorated in such a way that normal driver vision is materially impaired obstructed by any sticker, sign, poster or other thing or material placed over the window in such a way that normal driver vision is materially impaired window has an exposed sharp edge, is broken or part of window is window originally fitted with metal banding has any or banding a crack over 300mm long in any part more than 2 cracks over 150 mm long in any one piece of glass stone or shot injuries more than 40 mm in diameter two or more stone or shot injuries over 20 mm in diameter in any one piece of glass | 1, 2, 4, 5 |

c) material type Note: Applies to every side window. | c) is not marked as type AS-1, AS-2, AS-3, AS-10 or AS-11 Note: AS-3 is only acceptable for side windows to the rear of the driver location. Right Hand Drive Vehicles additional inspection requirements (see Appendix D). | 1, 2, 4, 5 |

d) tinting (MVAR 7.05(8)) Note: Applies to any window forward of the driver’s seat back. | d) any after-market tint (by film or any material or coating) is applied to any side window that is forward of the driver’s seat back tint or sunscreen other than that allowed by /Z26.1 standards any tint that is reflective type driver’s normal vision is materially impaired | 1, 2, 4, 5 |

14. Rear Window

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition | a) broken or clouded to such an extent that the driver is unable to see clearly 60 m to the rear window has an exposed sharp edge, is broken or part of window is a crack over 300mm long in any part more than 2 cracks over 150 mm long in any one piece of glass stone or shot injuries more than 40 mm in diameter two or more stone or shot injuries over 20 mm in diameter in any one piece of glass | 1, 2, 4, 5 |

b) material type Note: Rigid material may be used in place of glass or rigid plastic, when the vehicle is equipped with an outside rear-view mirror on each side. | b) is not marked as glass type AS-1, AS-2, AS-10 or AS- 11, or rigid plastic AS-4 or AS-5 | 1, 2, 4, 5 |

c) tinting (MVAR 7.05(8)) | any after-market tint is applied to the rear window if the motor vehicle is not equipped with outside rear view mirrors on the left and right side of the motor vehicle tint or sunscreen other than that allowed by /Z26.1 standards any tint that is reflective type driver’s normal vision is materially impaired | 1, 2, 4, 5 |

15. Interior Sun Visor

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) location | a) on driver’s side | 1, 2, 4, 5 |

b) attaching parts | b) bent, broken, or | 1, 2, 4, 5 |

c) adjustment | c) cannot be maintained in a set position | 1, 2, 4, 5 |

d) type | d) does not meet or applicable standard | 1, 2, 4, 5 |

16. Exterior Windshield Sun Visor

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

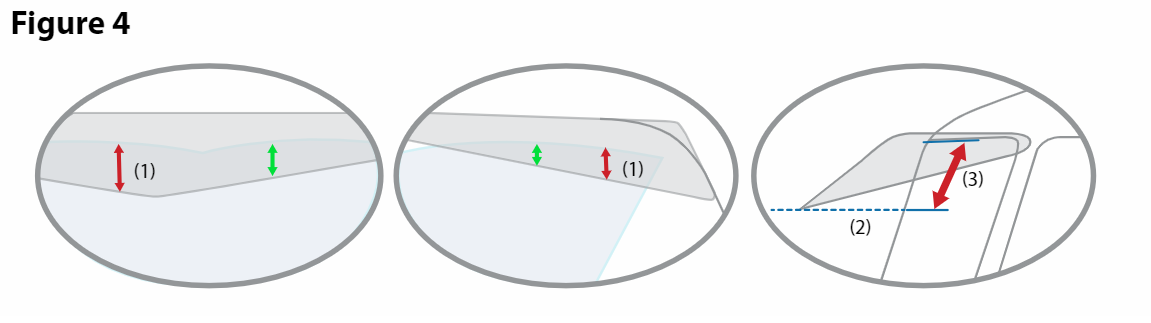

a) obstructed view | a) any part of an exterior visor, at any point:

| 2, 4, 5 |

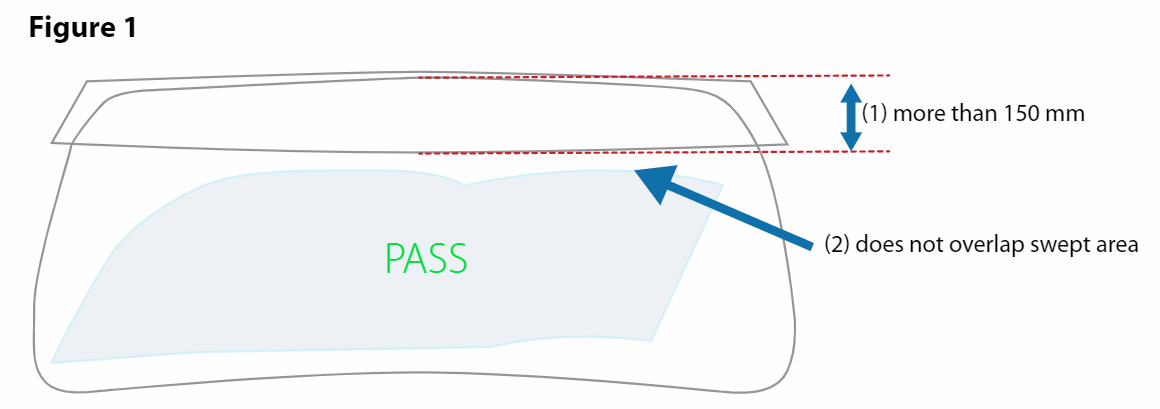

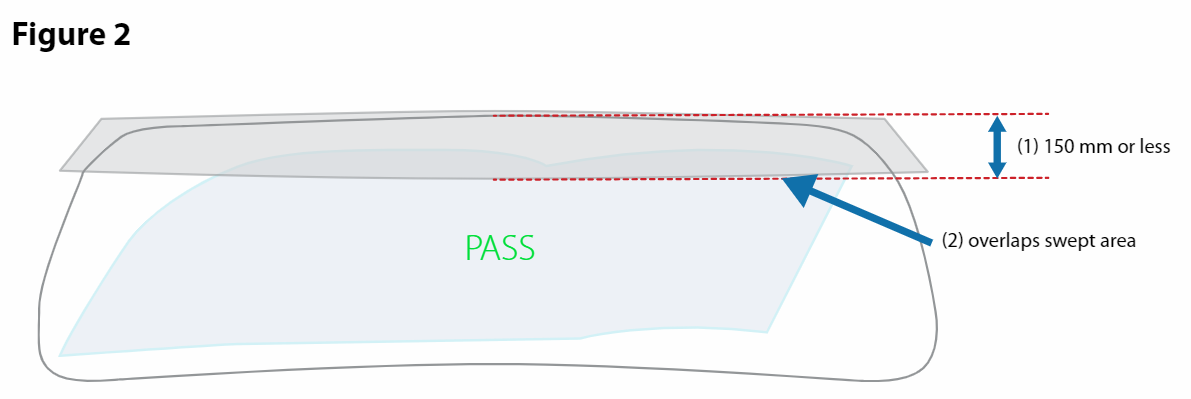

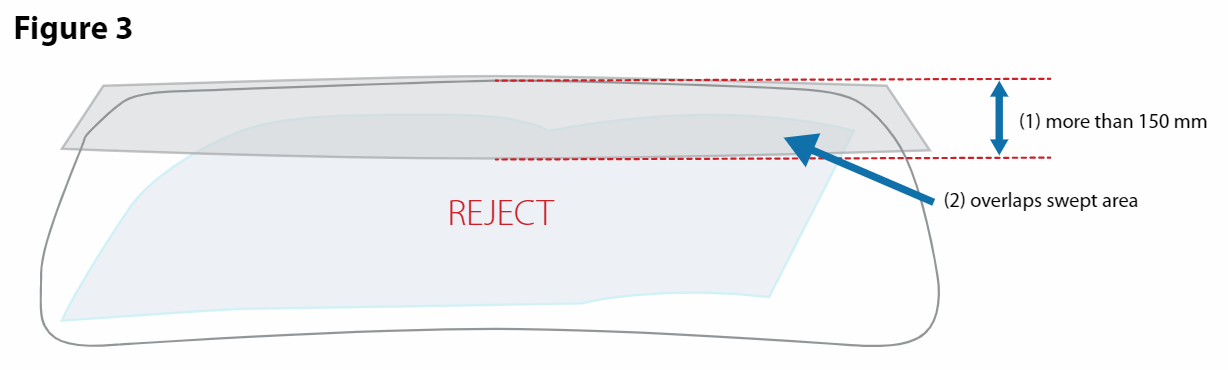

Additional Inspection Procedure(s): Sun Visor Measurement Location and Method

Note: “Swept area” means the portion of the windshield swept by an wiper blade attached to an wiper arm. | ||

i. any part of an exterior visor, at any point:

extends more than 150 mm below the upper edge of the windshield; and

overlaps the portion of the windshield swept by the wiper arm and wiper blade

17. Rear-view Mirror

Right Hand Drive Vehicles additional inspection requirements (see Appendix D).

Neighbourhood Zero Emissions Vehicles (NZEV) required equipment.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) location | a) required rear-view mirror is Note: Every vehicle requires an external rear-view mirror on the left side. When a vehicle does not have an interior rear-view mirror that provides an unobstructed view through a rear window, an external mirror is also required on the right side. require one mirror on each side. For additional requirements for driving school vehicles see Section 5 - Instruments and Auxiliary Equipment - Subsection 16 of this Vehicle Inspection Manual. | 1, 2, 4, 5, 6 |

b) view | b) view to the rear is obstructed to such an extent that the driver is unable to see clearly 60 m to the rear | 1, 2, 4, 5, 6 |

c) mount | c) broken, or fails to hold mirror in correct position | 1, 2, 4, 5, 6 |

d) glass condition | d) clouded, or deteriorated in such a way that normal driver vision is materially impaired Note: Driver’s vision is materially impaired if it meets the definition set out in section 29 of the Schedule to Division 7 of the MVAR. | 1, 2, 4, 5, 6 |

e) surface area of external mirror Note: mirrors are required to meet these same area requirements as per 111. When a convex mirror is installed onto a rear- view mirror, its area is included. | e) when non-mirror is used, surface area of the mirror is:

| 1, 2, 4, 5, 6 |

f) adjustment | f) required rear-view mirror not adjustable, or does not hold position | 1, 2, 4, 5, 6 |

i. an external rear view mirror is , obscured, or adjustment is seized

18. Seat

Note: This item does not apply to passenger seats on a . (See item 31 below for passenger seat requirements.)

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition Additional Inspection Procedure(s): | a) or mounting frame broken covering material torn and exposing a metal component or spring driver seat covering material torn more than 75 mm (3 in.) in length or 6,400 mm2 (9 in2) in area or 6.5 mm (1/4 in.) deep driver seat cannot be adjusted forward or backward driver seat on a school bus does not meet D250 Standard for the year of manufacture passenger seat cannot be adjusted forward or backward (if equipped) seat back recline mechanism fails to adjust seat pedestal removed seat assembly does not meet | 1, 2, 4, 5 |

b) seat position lock Additional Inspection Procedure(s): | b) seat adjustment fails to lock into position | 1, 2, 4, 5 |

c) head restraints (headrest) if equipped | c) , broken, not compliant | 1, 2, 4, 5 |

d) location | d) not in compliant location | 1, 2, 4, 5 |

e) seat | e) not securely attached to vehicle; or seat locking device (where fitted) not functioning properly, minimum seat height lower than 650 mm when vehicle is unladen | 6 |

i. driver’s seat , or fails to lock into position

19. Seat Belt/Occupant Restraint

Neighbourhood Zero Emissions Vehicles (NZEV) required equipment.

Right Hand Drive Vehicles additional inspection requirements (see Appendix D).

Note: Seat belts and occupant restraint system must comply with 208, 209 and 210 for year of manufacture. Seat Belts and Occupant Restraints are not required where a designated seating position has been removed.

Additional Inspection Procedure(s): Confirm the operation of each seat belt latch and retractor. If seat belt is down behind the seat cushion, pull it out and place it on the cushion.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) type and condition | a) , mounted, or not equipped at each seating position as originally required to meet applicable standards webbing material is broken, cut, frayed or torn air ride, hydraulic or spring seat does not have lap belts attached to the seat, or is not equipped with a secondary belt from the seat to the floor | 1, 2, 4, 5 |

b) anchor | b) broken, mounting or not located in an position | 1, 2, 4, 5 |

c) retractor | c) broken, mounting or fails to allow belt to extend to its maximum length or fails to retract properly belt retractor does not remove belt slack in all positions | 1, 2, 4, 5 |

d) belt release and buckle Additional Inspection Procedure(s): | d) broken, mounting or any part is not properly attached to the belt material latch fails to lock in position or fails to release easily when belt is under tension | 1, 2, 4, 5 |

e) supplemental restraint system (SRS) Additional Inspection Procedure(s): | e) an air bag is disconnected, , or not re-installed to service instructions the air bag indicator (SRS) lamp indicates a malfunction or fails to operate according to service instructions air bag has been deactivated permanently without a provision to turn off and on by a key lock, or does not have an illuminated message to indicate when the air bag has been switched off air bag cover | 1, 2, 4, 5 |

f) pre-tensioner and load limiter | f) pre-tensioner has been activated and system not repaired or replaced to meet load limiter has been activated and system not repaired or replaced to meet | 1, 2, 4, 5 |

g) onboard diagnostic | g) fails onboard diagnostic test | 1, 2, 4, 5 |

h) seatbelt indicator light | h) see criteria in Section 6, Item 4 of this Vehicle Inspection Manual | 1, 2, 4, 5 |

i. a required seat belt is or

20. Fender/Mudflap

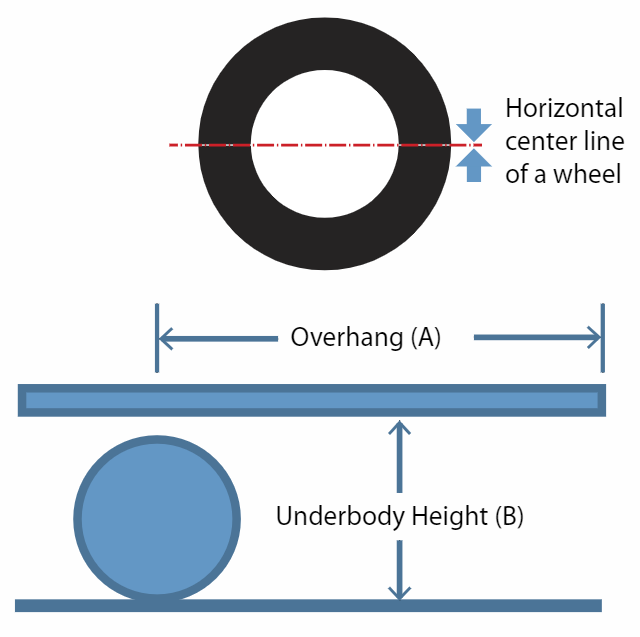

Note: A mudflap is required behind every wheel or axle group, where the full width of the tire is not enclosed by a body element, such as a fender, down at least as far as the wheel’s horizontal centre line, except as noted below.

Exceptions | |

|---|---|

A mudflap is not required where the body overhang is more than three times the underbody height. Overhang = (A) the distance from the vertical centre line of the tire to the end of the body Underbody height = (B) the distance from the bottom of the body overhang to the ground | |

On a vocational vehicle, if there is inadequate room for a full-size mud flap, or if a mud flap will interfere with the vehicle mechanical operation, then the presence, location and dimensions of mud flaps may vary from the standards. Authorized inspectors must ensure where a vocational vehicle does not meet the mud flap standards, that the spray and splash of water and mud to the rear of the vehicle is minimized. Vocational vehicle: means a truck chassis with permanently mounted equipment or body features intended to perform or support a specific job or group of related jobs and includes dump trucks, garbage trucks, concrete mixers, snowplows, and hydrovacs but does not include trucks solely intended to tow other vehicles such as a truck tractor or only intended to carry or transport goods such as van body or flat deck type trucks. | |

Mudflaps are not required on the following vehicles:

| |

Additional Inspection Procedure(s): If a vehicle described above that does not require mudflaps, is presented for inspection and meets all other applicable inspection criteria under section 8 of this Vehicle Inspection Manual, the inspection result on the report under “Section 8 - Frame and Body” MUST be marked as “Pass with caution” and include a comment indicating the exception that applied.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

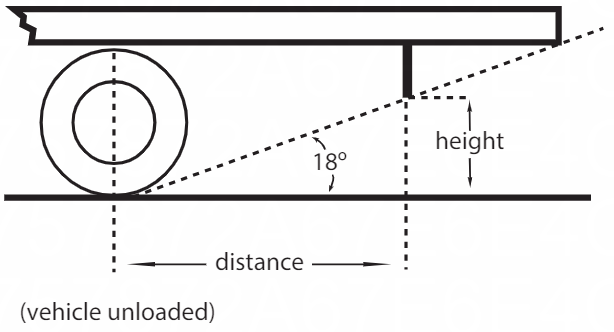

a) condition and location | a1) distance from ground to bottom of mudflap exceeds 1/3 of horizontal distance from mudflap to centre of wheel where the 1/3 rule cannot be applied due to vehicle configuration, the bottom of mudflap is more than 14 in. from ground, measured when vehicle is not loaded | 1 |

a2) fender or mudflap is broken, has mounting, is or fender or mudflap has a tear or wear hole exists that is larger than 100 mm across the longest dimension, or the aggregated longest dimensions of multiple holes in a single mudflap equal more than 100 mm the distance from the bottom of the mudflap to the ground exceeds 210 mm (8.25 in.) the mudflap does not cover the full tread width of the tire(s) the top of the mudflap does not reach up to the top of the tires or a body element | 2, 3, 4, 5 | |

a3) any fender, fender extension or mud-guard is , cracked or torn, or fairing cracked or torn | 6 |

i. required mudflap is

21. Landing Gear on Trailer

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) operation Additional Inspection Procedure(s): | a) binding, or seized | 3 |

b) condition | b) landing gear or brace is bent, broken or cracked mounting pad broken, or , or | 3 |

c) crank handle | c) cannot be stowed or secured so that it remains within the outer dimensions of the vehicle | 3 |

i. any part of the landing gear is or or so as to become detached from vehicle

22. Sliding Axle Assembly (Sliding Bogie) on Trailer

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) frame and sub-frame rail | a) welded or repaired in a way that does not meet bent, broken or cracked any attaching weld is broken or cracked perforated or separated due to corrosion between mount and frame member rusted or corroded to a depth sufficient to become weakened | 3 |

b) slider-guide/hold-down bracket & locking device | b) cracked or or fails to lock securely any lock pin is broken, cracked, disengaged or locking device (pin) is worn causing 25% or greater reduction in diameter locking-pin hole measures more than 25 mm larger than its original size | 3 |

c) stop | c) bent, cracked, or | 3 |

i. more than one-fourth of the slider locking pins or locking pin holes that are in use have any one of the following conditions:

locking pin is or not engaged

locking-pin hole measures more than 25 mm larger than its original size

the material from the hole in use to an adjacent hole, or the material from the hole in use to the edge of the rail, is torn or split

ii. more than one-fourth of the slider-guide/hold-down brackets are or disengaged

iii. the sliding suspension attachment member (undercarriage body rail) on either side has a crack of any length in more than 50 percent of its attachment welds

iv. a sliding suspension member’s (undercarriage body rail) attachment welds are cracked completely through along a 1.2 m continuous length of the body rail

v. a sliding suspension attachment member (undercarriage body rail) is cracked completely through along a 1.2 m continuous length

23. Aerodynamic Device and Attachment

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition and security | a) or any section has exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to driver, passenger, pedestrian or cyclist | 2, 3, 4, 5 |

i. aerodynamic device is so or it is likely to become detached from the vehicle

ii. any section has exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to driver, passenger, pedestrian or cyclist

24. Rear Impact Guard (RIG) on Trailer

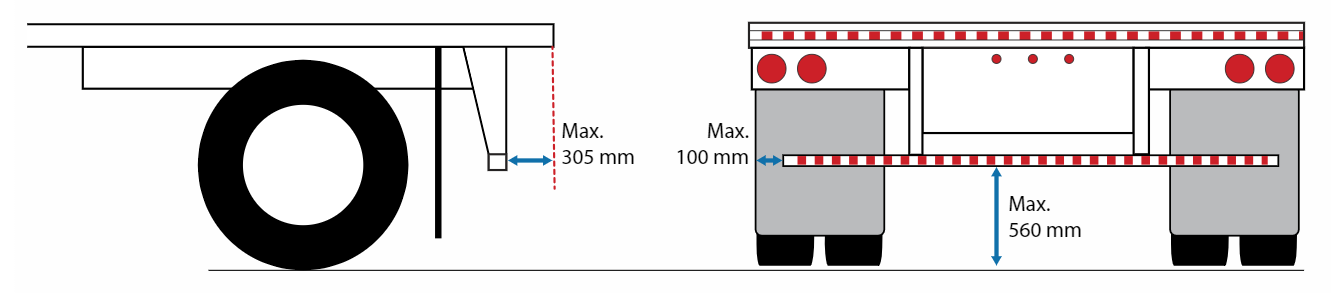

Note: Every trailer with a of 4,536 kg or greater manufactured on or after September 23, 2007, except as noted below, must be fitted with a rear impact guard (RIG) that meets the requirements of 223.

Trailers not required by to have RIG include:

pole trailer

pulpwood trailer

wheels-back trailer

trailer designed to be used as temporary living quarters

low chassis trailer

trailer designed to interact with, or having work performing equipment located in or moving through the area that would be occupied by a RIG

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

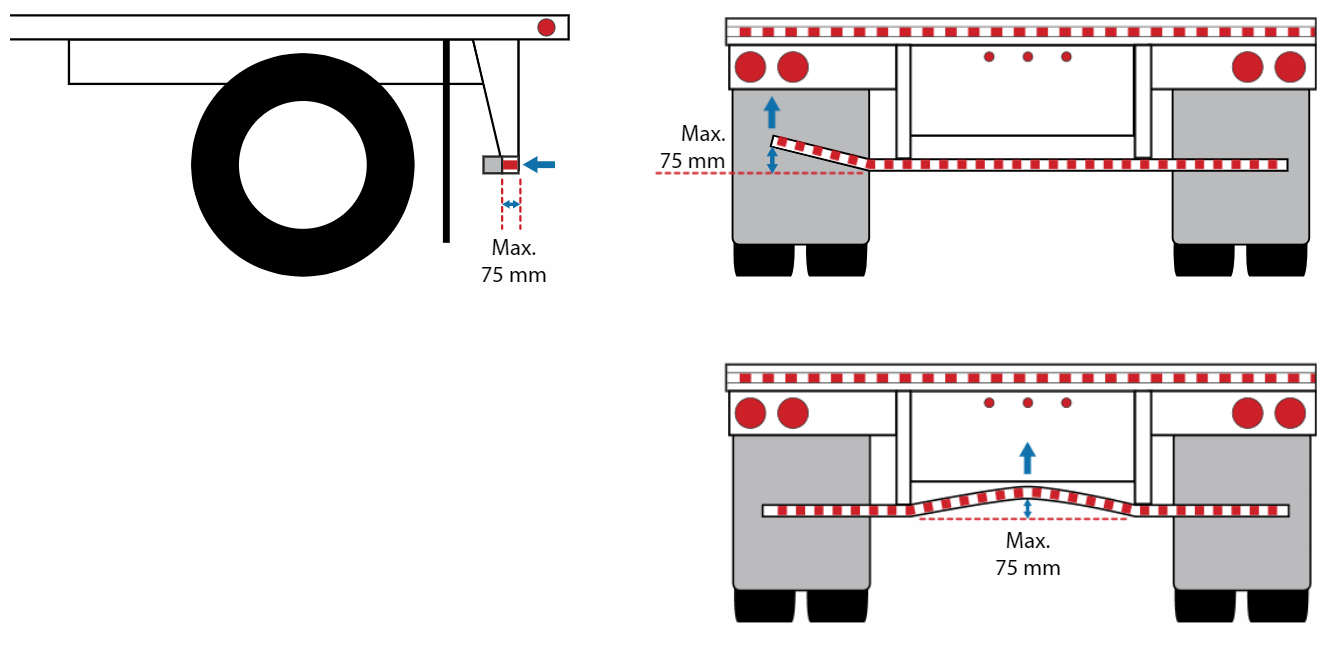

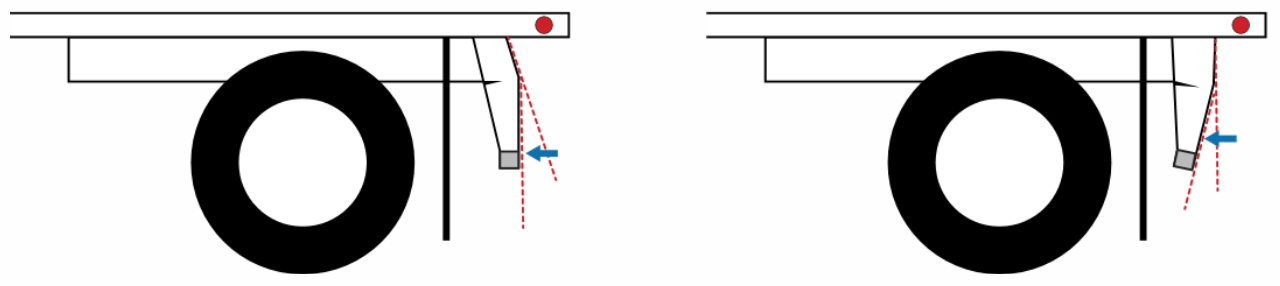

a) dimensions Note: All RIG dimensions are based on the trailer being in an unloaded condition, suspension at normal ride height and tires properly inflated. | a) RIG does not conform to dimensions shown in figure 1 below (based on - TMC RP 732) | 3 |

b) condition Note: Multiple bends are permitted. When there is visible damage to the RIG, also carefully inspect the trailer frame and floor for structural damage. | b) broken, or has cracked welds in the horizontal or vertical member or in the supporting structure or any attachment to vehicle structure the horizontal member is bent inward, downward, upward or outward, beyond 75 mm (see figure 2 below) the vertical supports and/or supporting structure are weakened, bent or distorted (see figure 3 below) | 3 |

i. any part of the RIG is so or it is likely to become detached from the vehicle

25. Floor Pan/Baggage Floor/Step Well on a

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) floor condition | a) bent or deformed in a way that causes unevenness in any aisle, improper attachment of any seat or interferes with any system or control cracked, split or has any non-manufactured hole that is not properly patched rusted or corroded sufficiently to result in structural weakness allows exhaust gases to enter occupant compartment any rivet is or | 4, 5 |

b) floor covering Note: Slip resistant covering is required on the passenger compartment floors and aisles of all buses. Floor covering is not required in baggage areas. | b) cracked, torn or worn through, or not sealed at seams or curled and posing a tripping hazard or improper type not a smooth surface material under the seats on a school , not a ribbed surface material in the aisle, or required ribbed surface of floor covering is worn smooth | 4, 5 |

c) step well condition Note: Slip resistant covering is required on all step tread surfaces. | c) bent or deformed in a way that causes unevenness on any step surface cracked, split or has any non-manufactured hole that is not properly patched rusted or corroded sufficiently to result in structural weakness nose of tread does not have band of contrasting colour (only applicable where a contrasting colour was originally equipped by ) | 4, 5 |

26. Interior Body and Fixtures on a

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) stanchion and guard rail | a) equipped stanchion is , support or fastener energy absorbing material is and exposing any area of metal with the longest dimension greater than 25 mm energy-absorbing material deeper than 6 mm, is on any one element, on one or more sections that equal more than 100 mm, when the longest dimension of all such areas are added together | 4, 5 |

b) grab handle | b) equipped grab handle is broken or on a school bus, drawstring block or security block (that prevents draw strings from being caught) is | 4, 5 |

c) retainer barrier on a school bus Note: A school bus must be equipped with a seat | c) , not located forward of any seat any part is not padded on the rear face on the upper 300 mm | 4, 5 |

d) metal condition | d) any metal is torn in a way that could be hazardous to a person | 4, 5 |

27. Service and Exit Door on a

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition and operation Additional Inspection Procedure(s): | a) binds or fails to lock securely mounting, or severely corroded in hinge area panel is corroded through welded or repaired in a way that does not meet door fails to operate or fails to latch on both primary and secondary latches gap exists that allows exhaust gases to enter occupant compartment | 4, 5 |

b) door openers and handles | b) broken, or catch or latch is broken, or | 4, 5 |

c) remote door operator | c) , or not equipped binds, jams or malfunctions manual override device on power operated door is or control is not accessible from seated driving position | 4, 5 |

d) door edge material | d) material is or torn strip seal along the bottom edge of the door is or torn or improper type of material | 4, 5 |

e) window of school bus door Note: Applies to school bus only. | e) has fog or visible moisture between panes fails to meet any of the following requirements:

| 5 |

i. door is or fails to remain in the closed position

28. Emergency Exit (Door, Window and Roof Hatch) on a

Note: Inspection must be conducted according to the . School buses must meet Applicable D250 for year of Manufacture.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) condition and operation Additional Inspection Procedure(s): | a) passage to any door is blocked release or latch is from the inside or outside hinge is fails to open fully and smoothly on a school bus, emergency exit door hold mechanism does not operate as required per applicable D250 standard | 4, 5 |

b) label and signage Note: Inspection must be conducted according to the . | b) fails to display required label or sign identifying emergency exit fails to display required label or sign displaying operating instructions | 4, 5 |

c) emergency door and roof hatch | c) interlock system on emergency door or roof hatch is | 4, 5 |

d) emergency exit window warning on a school bus | d) warning device or on emergency window | 4, 5 |

i. required and or marked emergency exits are , , or obstructed

ii. vehicle operates with emergency door locked

29. Passenger Compartment Window on a (Except Emergency Exit Window)

Note: Items a), b) & c) below apply to all passenger compartment side windows. School buses must meet Applicable D250 for year of Manufacture

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) operation Additional Inspection Procedure(s): | a) fails to open, close or latch as intended | 4, 5 |

b) condition | b) broken, exposed sharp edge, single pane glass is cracked or dual pane window is cracked on inside exposed edge is not banded on a school bus, double-paned windows or windows equipped with frost shields, are not fitted where required by the | 4, 5 |

c) material type | c) not marked as one of the two material listed below:

| 4, 5 |

d) window tint | d) aftermarket tint or sun screen is applied to the windows directly to the left and right of the driver (including windows in doors) on a school bus aftermarket tint or sun screen is applied to any window that is required to be double-paned by the | 4, 5 |

30. School Bus Exterior Mirror (Except Standard Left and Right Side Mirror)

Note: Applies to school bus only. School buses must meet applicable D250 for year of manufacture.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) left and right side convex rear-view mirror | a) required convex mirror is broken, , , , or fails to meet any applicable D250 requirement | 5 |

b) cross-over convex mirror Note: A school bus manufactured after November 29, 1997, requires two cross-over mirrors. | b) not equipped with required one, or two, fender- mounted or equivalent, cross-over mirrors mirrors fail to provide the driver with the required view of the front, and front-left and front-right sides of the school bus mirror, or mirror mounting, is or , or fails to maintain adjustment power operated mirror is mirror is broken, cracked or pitted, on an aggregated area larger than 5% of the mirror surface has any condition that deteriorates, or interferes with the normal view from the mirror | 5 |

c) mirror heating and controls Additional Inspection Procedure(s): Note: Confirm compliance based on vehicle age with the . Any amount of heat produced by the mirror is sufficient to indicate functionality. | c) | 5 |

i. mirror is , or ; obscured or seized

31. Passenger Seat on a

Additional Inspection Procedure(s): Manually check the condition and security of each passenger seat.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) frame and mounting | a) broken, or not securely attached to the floor or wall as required | 4, 5 |

b) seating surface | b) covering material is torn, exposing the seat base or springs padding or energy absorbing material thickness is reduced by more than 25%, over an aggregated area greater than 10% of the seating surface a tear in the covering is longer than 75 mm covering has a hole, or covering is , where the longest measurement across the area is more than 100 mm on a school bus, seat bottom is not secured to the frame | 4, 5 |

c) seat back and barrier surface | c) or a tear in the covering is longer than 75 mm covering has a hole, or covering is , where the longest measurement across the area is more than 50 mm energy-absorbing material is reduced in thickness by more than 25%, where the longest measurement across the area is more than 75 mm | 4, 5 |

d) location, position and capacity | d) does not meet /requirements on a school bus does not meet applicable D250 standard seating capacity exceeds maximum number indicated by the vehicle primary or secondary | 4, 5 |

i. seat frame not securely attached to the floor or wall as required

32. School Bus Body Exterior

Note: Applies to school bus only.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) paint | a) body is not the required colour hood is not the required colour bumper is not the required colour | 5 |

b) rub rail | b) broken, corroded, cracked, or torn sections, or removed repaired in a manner that does not meet any rivet is or bent and protruding from the side of the does not comply with applicable D250 standard for year of manufacture | 5 |

c) signs | c) any required sign is , not clearly visible and legible, , or fails to comply with all | 5 |

d) stop arm and control Additional Inspection Procedure(s): | d) red paint has faded to less than 70% of original intensity (minimum intensity is equivalent to Pantone® PMS 7607U) Note: Use an colour-reference chart as necessary. | 5 |

e) stop arm lamp Additional Inspection Procedure(s): | e) or fails to comply with an applicable requirement of the BC MVAR | 5 |

f) pedestrian crossing arm Additional Inspection Procedure(s): | f) bent, broken or incorrect length | 5 |

i. rub rail is protruding from the side of the

ii. any section has exposed sharp edge, is torn or protrudes out in a manner that could be hazardous to driver, passenger, pedestrian or cyclist

33. Auxiliary Compartment on a Bus

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) access and baggage doors Additional Inspection Procedure(s): | a) latch fails to hold hinge is broken, , or seized hinge mounting area is counter balance cable is frayed or will not maintain open position | 4, 5 |

b) passenger compartment baggage area partition | b) does not have a securely attached barrier, separating baggage from occupant seating area | 4, 5 |

c) overhead shelf/parcel rack | c) or mounting fastener is broken, or has no means of preventing articles from unintentionally falling out | 4, 5 |

i. access or baggage door latch fails to hold door in closed position

34. Sidecar

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) attachments | a) welded to frame, , , worn attachment points | 6 |

35. Accessories

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) canopy, cover, deck or equivalent | a) , mounted | 1, 2 |