Section 6 - Lamps

All inspection procedures are visual unless additional inspection procedures are indicated or where applied force is necessary to verify tightness and/or component security. The definitions can be found in the “Definitions and Acronyms” section.

Right Hand Drive Vehicles additional inspection requirements - see Appendix D.

1. Lamps

All lamps, lenses and bulbs must meet /standards. For the purpose of this section standards are considered equivalent to unless otherwise stated.

Additional Inspection Procedure(s):

All lamps mentioned except hazard lamps are to be inspected with head lamps and all other auxiliary lamps on and with brakes applied.

1.0. General

Item and method of inspection | Reject if | Inspection Class |

a) operation, condition and labeling of all lamps | a) fails to illuminate fully and correctly in response to the switch or control fails to turn off in response to the switch or control broken, cracked, , mounting or lens is clouded or reduces transmission of light, is not clearly visible or is covered in any manner moisture is present inside the lamp assembly any in headlamp assembly required for frontal illumination is 25% or more of LEDs of any one lamp assembly not required for frontal illumination are proper filament not lit does not meet standards not clearly labelled with or compliant Note: See Appendix A for details on requirements and compliant . | 1, 2, 3, 4, 5, 6 |

1.1. Required Lamps

Additional Inspection Procedure(s):

Test the operation of all required lamps, lamp switches and controls, and lamp indicators.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) headlamp Neighbourhood Zero Emissions Vehicles (NZEV) required equipment. | a) headlamp beam pattern is not directed toward right hand side of roadway headlamp aim adjusters , broken, , mounted , do not meet or bulb is installed in an incandescent headlamp housing headlamp switch, or beam (high and low) selector, is broken, , , does not meet height is not between 56 cm and 137 cm (22 and 54 in.) above road surface when measured at centre of lamp not two or four facing front as far apart as practicable not capable of displaying white light low-beam devices are not most outboard light source (or uppermost, if arranged vertically) in four-lamp configuration | 1, 2, 4, 5, 6 |

b) tail lamp Neighbourhood Zero Emissions Vehicles (NZEV) required equipment. | b) not equipped with a minimum of two lamps (see note below) facing the rear, located at rear of vehicle and as far apart as practicable Note: A may be equipped with only one tail lamp; and, a vehicle manufactured before January 1, 1959 may be equipped with only one tail lamp (MVAR 4.15). not capable of displaying only red light height is not between 38 cm to 183 cm (15 to 72 in) above the road surface when measured at centre of lamp | 1, 2, 3, 4, 5, 6 |

c) stop (brake) lamp Neighbourhood Zero Emissions Vehicles (NZEV) required equipment. | c) not minimum of two lamps (see note below) facing the rear, located at rear of vehicle and as far apart as practicable Note: A may be equipped with only one tail lamp; and a vehicle manufactured before January 1, 1959 may be equipped with only one tail lamp (MVAR 4.17). not capable of displaying only red light does not illuminate correctly when service brakes are applied height is not between 38 cm and 183 cm | 1, 2, 3, 4, 5, 6 |

d) centre high-mount stop lamp Note: Required on all passenger cars (manufactured on or after January 1, 1987), and on MPVs, trucks, and buses, less than 2032 mm in overall width and with a of 4536 kg (10,000 lbs) or less, manufactured on or after January 10, 1997. Not required on trailers. | d) not facing rear of vehicle not capable of displaying only red light does not illuminate correctly when service brakes are applied | 1, 2, 4, 5 |

e) turn-signal lamp Neighbourhood Zero Emissions Vehicles (NZEV) required equipment. Note: Not required on front of trailers. Note: Height requirements do not apply to highway construction vehicles, maintenance vehicles, tow cars or vehicles being towed by a tow car. | e) on a vehicle less than 2.05 m wide, control fails to cancel automatically when steering returns to centre not minimum of two facing the front, as far apart as practicable and capable of displaying flashes of white or amber light visible to the front not minimum of two facing the rear, as far apart as practicable, and capable of displaying flashes of red or amber light visible to the rear does not flash between 50 and 130 times per minute height is not between 38 cm and 183 cm Additional Inspection Procedure(s): | 1, 2, 3, 4, 5, 6 |

f) hazard warning lamp Note: Can operate same lamps as turn-signals. | f) broken, cracked, or control is broken, or hazard warning indicator lamp on instrument panel is the hazard warning lamps fail to meet any of the following requirements:

| 1, 2, 3, 4, 5, 6 |

g) side-marker lamp Note: A single lamp may serve as both a side-marker and a clearance lamp, provided it is clearly visible from both the side and the rear. Vehicles 9.1 m or more in length require amber intermediate lamps. Intermediate side-marker lamps are not required on vehicles less than 9.1 m in length. | g) amber intermediate side-marker lamps are or on a vehicle over 9.1 m in length not minimum of four in total, two at the rear and two at the front, facing the side not located as close to corners as practicable front are not amber in colour rear are not red in colour height is less than 38 cm (15 in) above road surface when measured at centre of lamp | 1, 2, 3, 4, 5 |

h) clearance lamp Note: Clearance lamps are required at the front and rear on all vehicles 2.05 m or more in width. Rear clearance lamps are not required on truck- tractors. | h) not minimum of four in total, located as far apart as practicable at the widest point of the vehicle not two facing the front, as high as practicable, amber in colour not two facing the rear, red in colour | 2, 3, 4, 5 |

i) identification lamp Note: Identification lamps are required at the front and rear on all vehicles 2.05 m or more in width, except as noted below. Rear identification lamps are not required on truck- tractors. Front identification lamps are not required on trailers. | i) less than six in total (three facing the front, amber in colour, and three facing the rear, red in colour) | 2, 3, 4, 5 |

j) back-up lamp Note: Back up lamps are required on all trucks, truck-tractors and buses manufactured after January 1, 1971. | j) not white in colour or not located at rear fail to illuminate with engine running and transmission in reverse gear | 1, 2, 4, 5 |

k) licence plate lamp | k) not capable of displaying only white light fails to illuminate licence plate so that the numbers on are legible from a distance of 15 m to the rear of the vehicle projects white light to the rear of the vehicle does not illuminate whenever the headlamps or parking lamps are illuminated | 1, 2, 3, 4, 5 |

l) daytime-running lamp (DRL) Note: Required on all passenger cars, MPVs, trucks, buses and manufactured after December 1, 1989. | l) not located on front of vehicle not white or yellow in colour not mounted at a height of not less than 30 cm and not more than 2.11 m DRL Switching: does not activate when the vehicle is set in motion does not remain activated until the vehicle’s engine is turned off does not deactivate while the lower beam headlamps are turned on does not deactivate when the front fog lamps are activated (for vehicles manufactured after September 1, 2020) if they also serve as front turn-signal lamps, do not deactivate when turn-signal is activated does not deactivate when the hazard warning signal is activated Note: Subject to criteria above, daytime-running lamps may only be deactivated:

| 1, 2, 4, 5 |

m) running lamps | m) the following lamps on a do not activate when set in motion under its own power and remains activated until the main electrical system is turned off or until it is put in the “accessory” mode of operation:

| 6 |

i. not at least one head lamp is operative on a power unit

ii. not at least one tail lamp is operative on the rear visible from 150 m

iii. not at least one stop lamp is operative on the vehicle visible from 150 m

iv. not at least one turn-signal lamp is operative on each side at the rear, visible from 150 m

v. not at least one turn-signal lamp is operative on each side at the front, visible from 150 m

vi. any required lamp is or obstructed during times when the lamp is required

1.2. Non-Required Lamps

Note: All non-required and non-opaque covered frontal lighting devices must meet applicable compliance standards for highway use.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) fog lamp (if equipped) | a) not located on front and/or rear of vehicle not white or amber in colour on front, red in colour on rear does not illuminate only when headlamp control is switched to low beam | 1, 2, 4, 5, 6 |

b) auxiliary high beam driving lamp (if equipped) | b) not maximum of two, located on front of vehicle not capable of displaying only white light does not illuminate only when headlamp control is switched to high beam not mounted at a height between 40 cm and 1.06 m from centre of reflector to the ground | 1, 2, 4, 5, 6 |

c) auxiliary low beam driving lamp (if equipped) | c) not located on front of vehicle not capable of displaying only white light not mounted at a height between 40 cm and 1.06 m from centre of reflector to the ground | 1, 2, 4, 5, 6 |

d) off-road lamps (if equipped) | d) not concealed with opaque covers | 1, 2, 3, 4, 5, 6 |

2. Reflex Reflector

Neighbourhood Zero Emissions Vehicles (NZEV) required equipment.

Note: A lamp’s lens may also function as a reflex reflector.

and vehicles require clearance reflectors if the vehicle resembles a model year for which clearance lamps were required.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) required reflectors Note: See Appendix A for details on | a) any required reflex reflector, or part of a reflex reflector, is broken, , , obscured or not clearly visible, not labelled to show compliance with , or standards | 1, 2, 3, 4, 5 |

b) rear reflector | b) not minimum of two, located as far apart as practicable not red in colour, between 380 and 1530 mm from centre of reflector to the ground Neighbourhood Zero Emissions Vehicles (NZEV):

| 1, 2, 3, 4, 5 |

c) front and rear side, and intermediate reflex reflector Note: Amber intermediate reflectors are required on all vehicles over 9.1 m in length. | c) amber intermediate reflex reflector is on a vehicle over 9.1 m in length not minimum of four in total, located as far apart as practicable, between 380 and 1530 mm from centre of reflector to the ground not two at the front, amber in colour not two at the rear, red in colour | 1, 2, 3, 4, 5 |

3. Retro-Reflective Marking

Note: See Appendix A for details on 108 requirements for retro-reflective markings.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) presence | a) any required section is retro-reflective marking is on:

| 2, 3, 4, 5 |

b) type/markings | b) consist of anything other than alternating red and white retro-reflective sheeting that is marked -C, DOT-C2 (50 mm wide), DOT-C3 (75 mm wide) or DOT-C4 (100 mm wide) Note: Optional in Canada - Rear lower body and side conspicuity treatment may also be solid white, solid yellow, or white and yellow. for the purpose of school buses, consists of anything other than conspicuity markings as specified in the applicable D250 standard | 2, 3, 4, 5 |

c) condition | c) peeling off or reflective properties are compromised on an area exceeding 77 cm2 (12 in2) of the entire surface of the required reflective material Note: On 50 mm wide material, this means a total length of 15 cm having some loss of reflective property. | 2, 3, 4, 5 |

d) location and type | d) retro-reflective markings fail to meet the requirements of 108 as shown in Appendix A | 2, 3, 4, 5 |

e) location of retro-reflective material voluntarily applied to straight truck Note: Having the retro-reflective material too close to a lamp makes it more difficult to see the lamp. | e) red coloured retro-reflective marking is located closer than 75 mm to the edge of the lens of any amber lamp white coloured retro-reflective marking is located closer than 75 mm to the edge of the lens of any lamp | 2, 3, 4, 5 |

i. more than 50% of retro-reflective material of any required section is compromised or

4. Instrument Panel Lamps

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) operation Note: Minor loss of illumination of some parts of the instrument panel is not cause for rejecting a vehicle. | a) any of the following indicators are or :

Additional Inspection Procedure(s): SRS diagnostic test results must be recorded.

| 1, 2, 4, 5, 6 |

5. Headlamp Aim

Additional Inspection Procedure(s):

Check headlamp aim using equipment specifically designed for such use, or an aiming screen, following the equipment instructions.

Ensure that the equipment is calibrated according to the instructions.

Aiming Screen Method

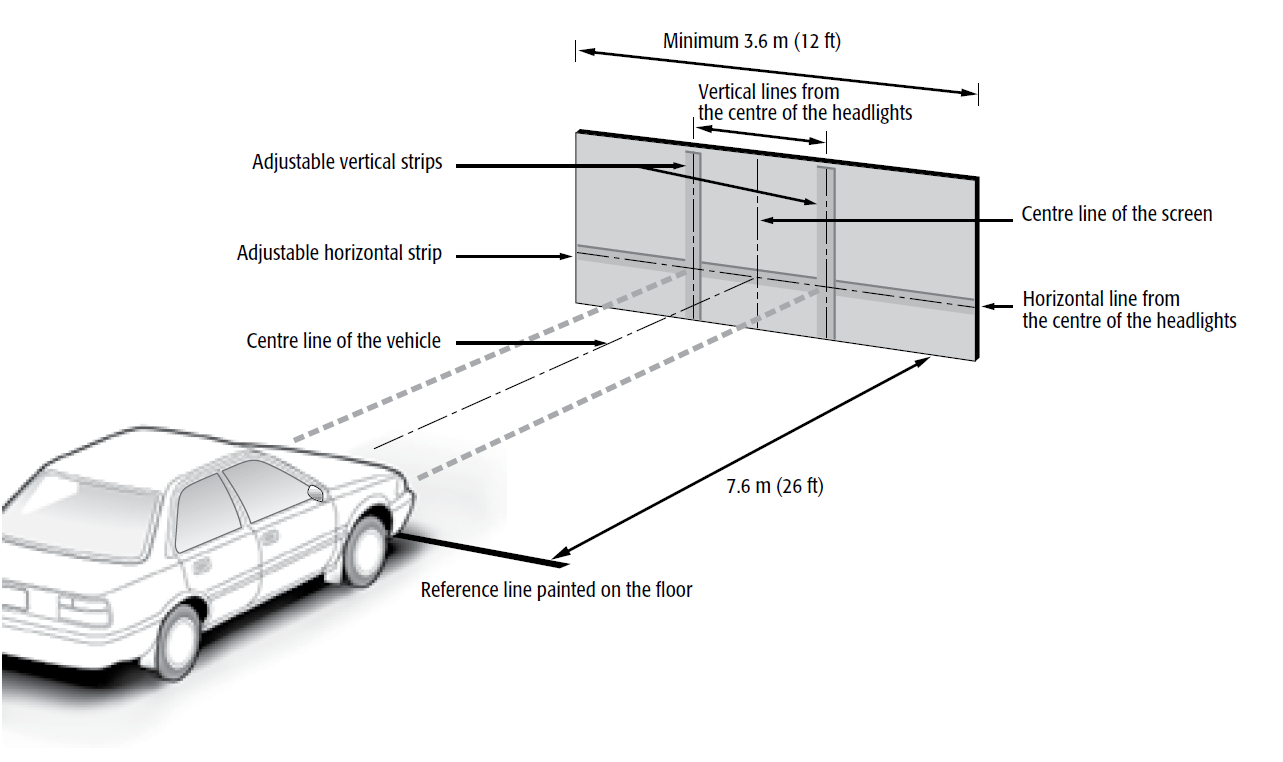

A. Aiming Area Required

It is required to have a specific aiming area in a darkened location. This should be sufficient for the vehicle plus an additional 7.6 m measured from face of lamps to the front of the visual screen.

The floor on which the motor vehicle rests must be flat and level with the bottom of the screen.

B. Aiming Screen

If a regular commercial aiming screen is not available, the screen may consist of a vertical wall having a clear uninterrupted area approximately 1.8 m high and 3.6 m wide.

The surface should be finished with non-gloss white finish. Adjustable black strips should be used as guidelines.

After the aiming screen has been set up in its permanent location, it is necessary to have a reference line on the floor directly under the lens of the lamps to indicate the proper location of the headlamps when they are being aimed. This reference line should be parallel to the aiming screen and exactly 7.6 m from it.

Inspect headlight alignment using a screen as indicated below:

Place the vehicle so that it is facing the screen and the headlights are directly above the reference line on the floor.

Align the centre of the vehicle with the line down the centre of the screen:

Mark the centre of the windshield and rear window. It is not necessary to mark the windshield if the vehicle has a hood ornament.

Look through the centre of the rear window and adjust the position of the vehicle so that these two points are aligned with the centre line on the screen.

Measure the distance from the ground to the centre of the headlight lenses and transpose this measurement onto the screen so as to obtain the horizontal line from the centre of the headlights.

Measure the distance between the centre of headlight lenses and transpose half of this distance onto the screen on each side of the centre line so as to obtain the vertical lines from the centre of the headlights.

Note: If the vehicle is equipped with adaptive headlights, the angle of the steering wheel must be neutral.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

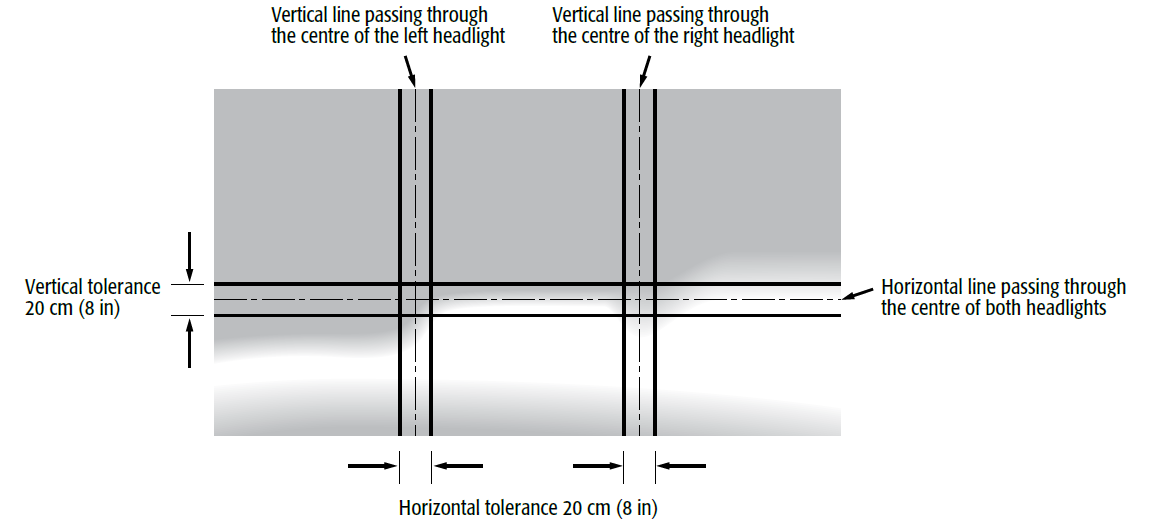

a) low beam Note: Headlamp aim must be checked when vehicle is unloaded. | a) not within specification, or when specification is not available, when positioned 7.6 m from aiming screen does not comply with the requirements below: horizontal alignment the left extremity of the high-intensity zone is more than 10 cm (4 in) on the left or right of the vertical line passing through the centre of the headlight. vertical alignment the centre of the high-intensity zone is more than 10 cm (4 in) above or below the horizontal line passing through the centre of both headlights. | 1, 2, 4, 5 |

With the vehicle correctly positioned, switch the headlights on to the low beam position and check the centre of the high-intensity zone on the screen. | ||

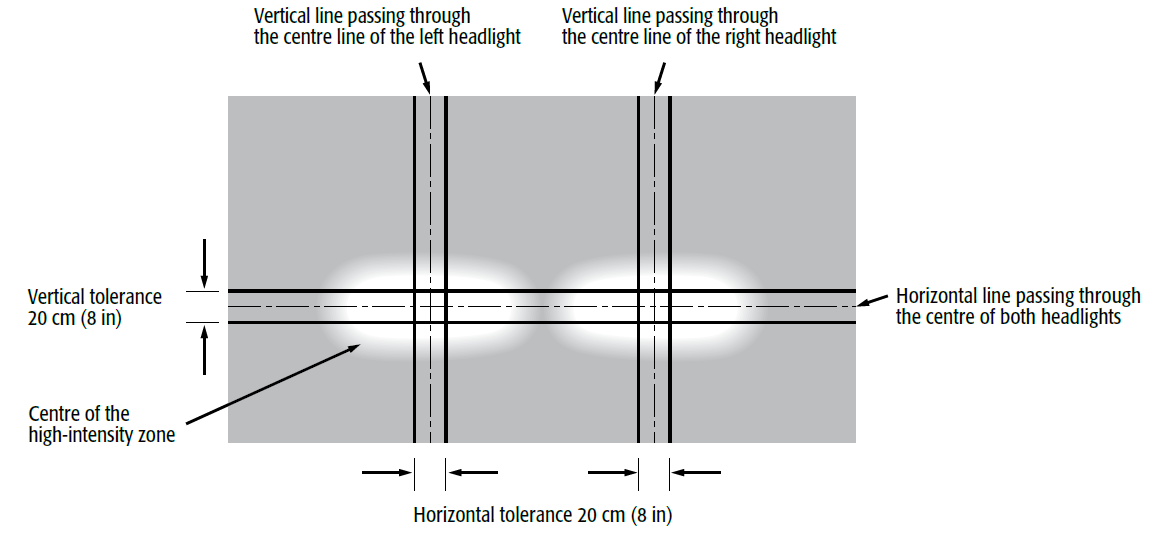

b) high beam Note: Headlamp aim must be checked when vehicle is unloaded. | b) not within specification, or when specification is not available, when positioned 7.6 m from aiming screen does not comply with the requirements below: horizontal alignment the centre of the high-intensity zone is more than 10 cm (4 in) on the left or right of the vertical line passing through the centre of both headlights. vertical alignment the centre of the high-intensity zone is more than 10 cm (4 in) above or below the horizontal line passing through the centre of both headlights. | 1, 2, 4, 5 |

With the vehicle correctly positioned, switch the headlights on to the high beam position and check the centre of the high-intensity zone on the screen. | ||

c) headlamp aim adjusters | b) broken, , mounting or | 1, 2, 4, 5 |

i. aiming of headlamp is so severely out of alignment that it is likely to impair the vision of the driver or other motorists

6. Interior Lamps on a

Note: Inspection must be conducted according to the requirements of the BC MVAR and applicable D250, D409, D435 & D436 Standard. Inspector must be familiar with the .

Additional Inspection Procedure(s): Activate interior lamps, then operate each entrance door. Emergency exit doors are excluded.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) step well lamp | a) not white in colour, or fails to illuminate step well area stays on when door is closed | 4, 5 |

b) aisle and overhead lamps Note: Required on commercial passenger vehicles vehicles. | b) more than 10% of the lamps on any lamp circuit are | 4, 5 |

c) accessible vehicle lighting | c) lamp installed for accessibility device (such as a ramp or lift) is or | 4, 5 |

7. School Bus Additional Lamps

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) alternating warning lamps Additional Inspection Procedure(s): | a) not equipped, or do not operate as required by the applicable D250 Standard 25% or more of LEDs of any lamp assembly are alternating warning lamp indicator on instrument panel or switch is or | 5 |

b) strobe lamp (if equipped) | b) does not operate as required by the applicable D250 Standard | 5 |

c) service door exterior lamp Additional Inspection Procedure(s): | c) not equipped, or does not operate as required by the applicable D250 Standard | 5 |

i. on a school bus, alternating overhead warning lamps are or obstructed

8. School Bus Reflective Tape

Note: School buses manufactured on or after March 31, 1998, must be fitted with conspicuity markings as per D250.

Item and method of inspection | Reject if | Inspection Class |

|---|---|---|

a) rear | a) not two horizontal strips from left to right corners: one strip above the rear window and door, the other strip above the rear bumper. not two vertical strips, one at the left corner and one at the right corner, connecting the horizontal strips. | 5 |

b) sides | b) not two horizontal strips extending the length of the bus body: one strip above the windows, and the other between the floor line and belt line not two vertical strips, one at the left corner and one at the right corner, connecting the horizontal strips the longitudinal length of the material does not cover and is not visible on a minimum of 90% of the bus passenger compartment | 5 |